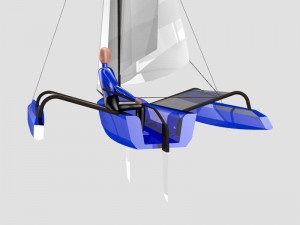

This boat created immediate appeal to beginning and intermediate sailors. It offers much of the speed experience of a high performance skiff in a stable and predictable platform that is really tough to capsize. The Weta is one of the first boats to encourage family participation and reintroduces the waterborne fun of the beach sailing culture, established way back in the late 60’s with the intro of the Hobie catamaran.

A brand new, factory built Weta goes out the door for USD $11K. Realistically speaking, this isn’t an in surmountable amount of money for a factory produced, brand new carbon trimaran. It is, however, quite a lot of money for most casual recreational enthusiasts and the folks who like to build their own boats… especially when you consider the rugged economic conditions we all face these days.

So, I decided to take a whack at producing a set of plans for a homebuilder’s version of a Weta-like hybrid

that could be  buildable in the neighborhood of $5600 ready to sail with a new mast, sails and trailer. I’m calling the new boat Montage, as it is an assemblage of concepts that fill the slot between a performance skiff and a small, quick trimaran. This boat will appeal to sailing enthusiasts from kids to codgers who just want to get out on the water and have a fun and fast experience without breaking the bank.

buildable in the neighborhood of $5600 ready to sail with a new mast, sails and trailer. I’m calling the new boat Montage, as it is an assemblage of concepts that fill the slot between a performance skiff and a small, quick trimaran. This boat will appeal to sailing enthusiasts from kids to codgers who just want to get out on the water and have a fun and fast experience without breaking the bank.

The estimated $5600 figure represents a boat with a whole host of brand new parts. For the clever builders out there, the Montage could be even less expensive if they can find a used 470 rig, perhaps a used small craft, or beach cat trailer that could be modified to fit the hull design and even a collection of hardware in good condition. The Montage is a very light boat at right around 235 lbs., so you do not need to buy a heavy duty trailer.

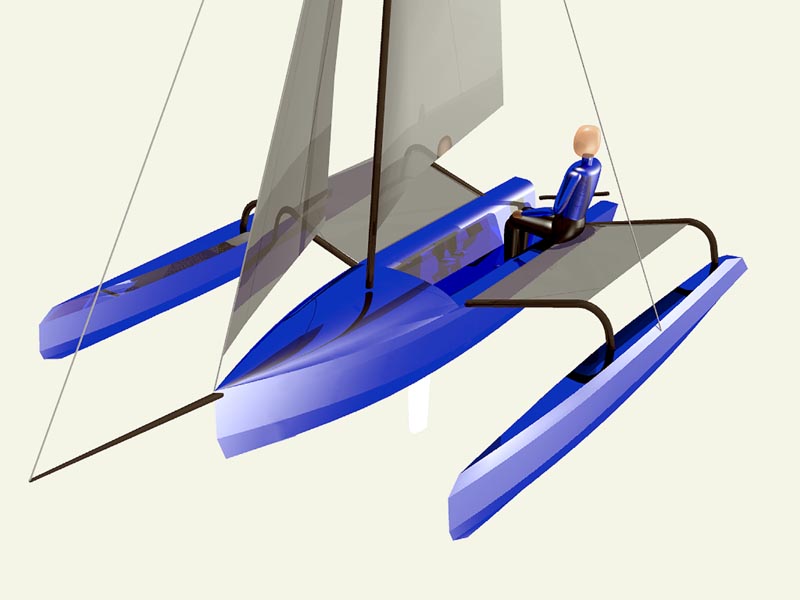

After a dozen different sketches of boats that fit the general design motif, I settled on a plywood multichine hull design that had virtually the same dimensions

After a dozen different sketches of boats that fit the general design motif, I settled on a plywood multichine hull design that had virtually the same dimensions

as the manufactured version. When I projected the hull panels to a two dimensional layout, though, I saw that I was going to be wasting a good bit of plywood by going with a 14′ 5″ boat that mimicked the dimensions of the production version.

I went back to the drawing table and reconfigured everything so that the longest hull panel was going to just fit on a couple of sheets of marine ply laid end to end. The main hull also got just a bit wider in the process of lengthening the boat. Where the factory boat uses carbon fiber on foam cores for its structure, the Montage will be a 4mm marine plywood design with full fiberglass/epoxy sandwich laminates inside and out. The foredeck and the cockpit seating transitions are strip-built in Red Cedar to give the overall appearance of the boat a smoother, more organic feel than straight plywood panels.

The amas for Montage came from a 16′ trimaran design that I had already done and required minimal re-design to work with this boat. The amas are also designed as multichine ply forms with pretty high volume shapes well forward and a water shedding deck form that will helps to keep them riding high even when driven hard. Ama displacement is 100% of the all-up boat weight when sailing.

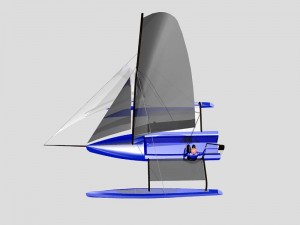

Montage Specifications

LOA 15′ 6″

BOA 12′

BOA main hull 41″

Main 110 sq. ft.

Jib 38 sq. ft.

Screacher 102 sq. ft.

Displacement 650 lbs.

Weight 235 lbs.

The aka beams are anodized aluminum instead of carbon tubing. The inboard ends fit into fairly burly sockets in the hull and are held in place with quick release pins. Flat deck flanges on the ama ends are welded in place and bolted to the amas. The amas are removable from the aka tubes for repair or maintenance, but otherwise stay mounted, along with the trampolines, as complete units.

The mast is also anodized aluminum. The boat uses the same mast section as the 470 dinghy, which is a Proctor Cumulus section. This mast is available on the used market with a little bit of hunting around. If you want it all and have the money, then there’s a very cool, filament wound Forte carbon spar available with very close specs to the Proctor that will rock your world. http://fortecarbon.com/

Making these two changes from the benchmark, all-carbon Weta to an aluminum spar and tubing keep the costs down, with but a slight weight penalty over all-carbon parts. If you find a used mast, the savings will be even more substantial.

The mainsail and the jib will be built in Dacron instead of a more expensive fiber/Mylar laminate sail. The jib is a self-tacking blade. The main is a boomless design, which will keep head bonking incidents out of the picture while sailing. The screacher is furled from the bowsprit for simple convenience.

The mainsail and the jib will be built in Dacron instead of a more expensive fiber/Mylar laminate sail. The jib is a self-tacking blade. The main is a boomless design, which will keep head bonking incidents out of the picture while sailing. The screacher is furled from the bowsprit for simple convenience.

I have found that the more expensive sailcloth laminates are capable of driving the boat just a bit faster, but for the average recreational sailor, they will hardly ever make a difference compared to more forgiving sails in Dacron. Dacron is much easier to maintain, lasts longer, is a lot more tolerant of UV exposure and can be repaired by any sail loft wherever you go. If the builder of the Montage really wanted to, they could buy a set of sails in something like Pentex laminate instead and they’d have that hot, performance boat look that some desire along with just a bit more zip under sail.

The overall design of the foils and their operation is pointed directly at the needs of a recreational sailor. The boat uses a centerboard for ease of use

and pretty much no-brainer beaching. Likewise, the rudder is a flip-up style unit that eliminates the problems of hitting  underwater objects. The foils will be built with template shaped cedar cores having a white ash stringer for stiffness and then glassed for durability.

underwater objects. The foils will be built with template shaped cedar cores having a white ash stringer for stiffness and then glassed for durability.

The aluminum aka tubes will be sold pre-bent and ready to install on the amas. If the builder has access to a good mandrel bending facility that can handle the OD/ID specifications of the tubing, they can fabricate their own tubes to supplied specs.

The Montage is designed to be a really fun day sailing machine that can generate near performance skiff sailing speeds while offering a hugely stable platform for recreational sailing. Construction of the boat is very straightforward in marine plywood with glass/epoxy laminates and can be easily built by any sailing enthusiast who has household handyman skills with tools. The Montage has been created to offer homebuilders an opportunity to enjoy this style of family sport boat at a completed cost that is far less expensive than the manufactured version.

CHRIS OSTLIND

Lunada Design